Laser cutting

Laser metal cutting is a modern technique that uses a concentrated beam of light from a laser to make cutouts of metal plates or sheets accurately and effectively.

Plasma and autogenous cutting

Plasma cutters work on the principle of cutting in a narrow stabilised electric arc which is pushed into the material at high speed with the help of driving gas.

Deburring

Grinding machines for double-sided deburring and rounding of edges on laser cut-outs or parts cut on a die-cutting press.

Straightening

We do straightening of laser-cut parts and cut-outs on an ARKU FlatMaster 88160 hydraulic cylindrical straightening machine.

CNC bending

CNC bending is an advanced sheet metal fabrication process that uses computer-controlled bending machines to create precise bends and curves in metal materials.

Welding

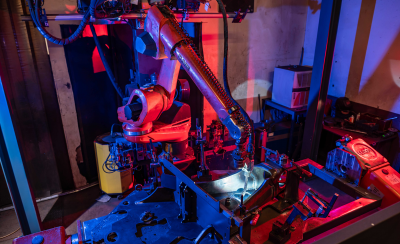

We offer productive welding of parts on 5-axis CLOOS welding robots:

Blasting

Metal blasting and sandblasting are important processes for maintaining and improving the surface quality of metal materials. The choice of method depends on the type of material, the surface treatment requirements and the type of final use.

Machining technologies

We offer CNC machining, milling, turning, drilling and grinding. We process steel, non-ferrous metals, aluminium and plastics.

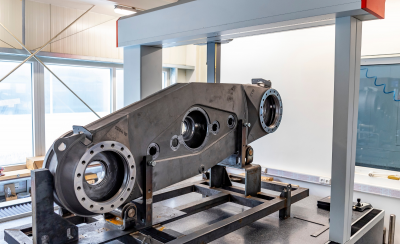

3D measurements

Precision in every detail from start to finish. 3D coordinate measuring machines allow us to measure products, parts and components very accurately.

Ultrasonic measurement

Precision in engineering manufacturing is crucial and as part of our plant technology we offer our customers ultrasonic precision measurement equipment.

Painting – powder coating

Powder coating enables the creation of a uniform, durable and aesthetically pleasing surface on a wide range of products and components.

Wet painting

In addition to powder coating, we also offer wet painting.